| 原産地: | 中国(本土) | コンダクターのサイズ: | 11 - 20 AWG | 銘柄: | Hejin | 接触の数: | 11 - 20 | モデル番号: | joint | タイプ: | 電力配分 | Technique: | Solid-Liquid machining processing | Material: | Copper T2, Aluminum 1060 | Specification(thickness * width): | 0.1mm-15mm*30mm-1000mm | Copper and Aluminum weight ratio: | Cu:AL: 32%-40%: 60%-68% | Copper and Aluminum volume ratio: | Cu:AL: 15-20: 80-85 | Density(g/cm3): | 3.5-3.9 | Resistivity(Ωmm2/m): | <0.019 | Tensile Strength(N/mm2): | More than 120 | Elongation(%): | 27-38 | Peeling Strength(N/mm): | more than 12 |

包装

| 包装: | 標準的な輸出木製ケースや要求など |

仕様

Product Information 1, Advantage

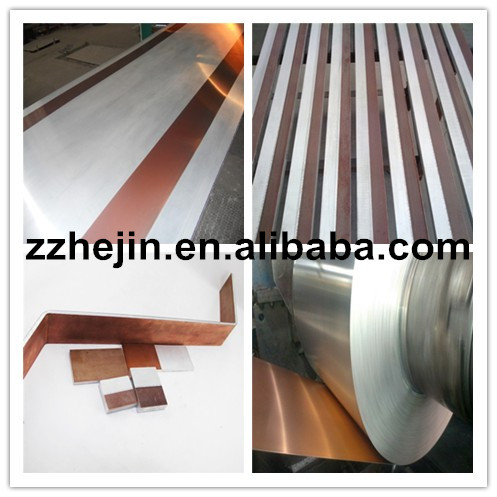

Our copper aluminum bi-metal which produced by innovative patent technology——Solid-Liquid machining processing technique to bond copper and aluminum permanently and firmly, with higher electric conductivity, lighter & lower cost than pure copper, we could meet all thickness between 0.15mm to 15mm in ratio of 20Cu:80Al by thickness for Cu-Al Bimetallic sheets, while unlimited for length and area.

2, Specification:

Weight Display in Common Specification |

|

|

|

|

|

| ||

Specification a*b(mm) | 3*30 | 3*40 | 3*50 | |||||

Weight/meter(kg) | 0.31 | 0.42 | 0.53 | |||||

Specification a*b(mm) | 4*40 | 4*50 | 4*60 | 4*80 | ||||

Weight/meter(kg) | 0.56 | 0.7 | 0.84 | 1.12 | ||||

Specification a*b(mm) | 5*40 | 5*50 | 5*60 | 5*80 | ||||

Weight/meter(kg) | 0.7 | 0.875 | 1.05 | 1.4 | ||||

Specification a*b(mm) | 6.4 | 6*50 | 6*60 | 6*80 | 6*100 | |||

Weight/meter(kg) | 0.84 | 1.05 | 1.26 | 1.68 | 2.1 | |||

Specification a*b(mm) | 8*50 | 8*60 | 8*80 | 8*100 | 8*120 | 8*200 | ||

Weight/meter(kg) | 1.4 | 1.68 | 2.24 | 2.8 | 3.36 | 5.6 | ||

Specification a*b(mm) | 10*60 | 10*80 | 10*100 | 10*120 | 10*150 | 10*200 | 10*250 | 10*300 |

Weight/meter(kg) | 2.1 | 2.8 | 3.5 | 4.2 | 5.25 | 7 | 8.75 | 10.5 |

3, Characteristics:

Cu-Al clad plate is a new technical material, based on different industry needs,formed by advanced machining processing technique: Solid-Liquid machining processing technique to bond copper and aluminum in oxygen-free environment permanently and firmly, which decided the alloy and base material characteristic are better preserved. It is suitable for continuous automatically manufacture and does not need other manufacture process, such as welding or soldering after its formation. Beside, Cu-Al clad plate is a saving of precious metal, keeping low cost and consistency of social development. It is used for all sorts of electrical component production, such as, Small Circuit Breakers, AC Contactors, Contactor Relay, Connectors, Switchers, and Automobile Radiators, etc.

1) Proportion of Copper/Aluminum is 2:8 and the proportion could be adjusted by customer's demand.

2) Single and double side copper clading are available.

3) Proceed continuous coil clading production without welding line. Therefore, the consistency of thickness is stable and very suitable for mass stampling production.

4) Resistance to corrosion and high temperature (500degree c without separation).

5) With good stability, excellent deep drawability and tensile properties, it can even bear 90°bend without separation.

6) With an electrical conductivity of 98% or more, it can completely replac pure copper by saving cost 64% under same volume.

7) The dimension can be produce as requested.

4, Main Application:

a. Electric power industry (conductive industry)----Mainly use bimetal copper on both side, aluminum between

b. Decoration industry----Mainly use bimetal with single side copper

c. Arts and crafts

d. Commodity

Contact us now for more professional information!

Welcome visit our factory!